Wind power

What we offer?

TECHNICAL STUDIES AND DESIGN OF TOWERS

Our ultimate objective is to achieve the optimum solution for our customers’ needs. The technical know-how and experience gained

during almost a decade allows us offering the following technical services:

- Preliminary studies of viability.

- Cost assessments of different alternatives.

- Study of local standards.

- Complete detail design of towers and foundations.

- Obtaining of design certifications.

- Detail analysis of critical components (e.g. using FE models).

- Tower instrumentation and data analysis.

- Design of tests and examination of results

STRUCTURAL DESIGN

The precast concrete technology applied to wind turbine platforms constitutes a unique technique where a broad range of specific fields of knowledge merge, among others:

- Design of reinforced and prestressed concrete structures.

- Design of steel structures.

- Comprehension of wind turbine loads.

- International and local concrete and steel codes.

- International standards for wind turbine structures and loads.

- Certification guidelines and requirements.

- Dynamic analysis of structures.

- Awareness of local requisites and determinant factors.

Additionally, we regularly work with engineering companies worldwide (e.g. United States, Canada, Mexico, Brazil, Germany) and also collaborate with universities and research centers (e.g. Tecnalia, Universitat Politècnica de Catalunya, Tianjin University, etc.).

INTERNALS DESIGN

Besides the obvious structural functionality requisites, precast concrete towers shall also satisfactorily fulfill other requirements in terms of accessibility and maintenance of the turbine and all its components. This is achieved by means of various internal elements, whose design shall take into account both the structural details of the tower and the definition of the manufacturing and erection processes.

The design criteria of these internal elements for concrete towers is different from those considered when dealing with steel towers, since the priority shall be to allow placing as many components as possible in the production plant, in order to reduce and simplify the assembly operations on site and, consequently, optimize the overall cost of the internals.

Windtechnic Engineering provides expertise in designing, manufacturing and assembling internals for wind turbine towers according to several internationally recognized standards, such as IEC, EN and OSHA requirements.

MOLDS DESIGN AND MANUFACTURING SUPPORT

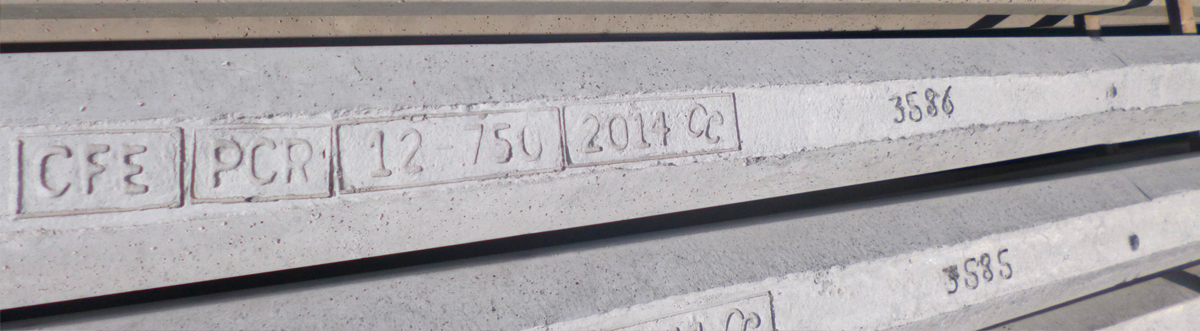

The pieces of which a wind turbine mast consists are characterized by their large dimensions and by very demanding tolerance requirements, which are generally lower than for any other precast concrete piece used in civil works. The design optimization of these concrete pieces leads to strict thicknesses and, consequently, to very low tolerances. In order to obtain a minimum final tolerance, the design must be adequate and the manufacturing process has to be capable of minimizing the tolerances.

In mould manufacturing, the steel qualities, welding and painting procedures and maximum tolerances demanded must meet the European Standards. The moulds manufactured in different countries are constructed in agreement with local standards and materials. To this end, Windtechnic controls the manufacturing of moulds in situ. Moreover, we demand and advise the manufacturer so as to guarantee a quality up to the standard demanded by wind energy industry.

DESIGN OF PRODUCTION AND ASSEMBLY PROCESSES AND QUALITY MANAGEMENT. SUPPORT ON SITE.

In order to develop a product fulfilling all the stringent technical requirements and assuring the highest quality level at a competitive price, the manufacturing and erection processes, as well as the quality control requisites, shall be considered in detail from the very beginning of the design process. This can only be achieved by an appropriate industrialization of the production and assembly processes.

Windtechnic’s international experience in manufacturing and erecting precast concrete towers for wind turbines is proven by the production inspections (IPE) carried out by independent certification institutions in those facilities run or supervised by our personnel and it covers all project phases: from the selection and inspection of local manufacturers, until the certification of the assembly process.

CERTIFICATION

Design certification of wind turbine towers is essential to guarantee compliance with applicable international codes and assure highest quality standards. Due to this fact, we have worked in the past few years with several distinct certification institutions, such as Germanischer Lloyd (GL), Det Norske Veritas (DNV), TÜV Nord and Huanghe Design Institute. Hence, we can offer a wide variety of precast concrete solutions for wind turbine platforms, all of which are approved by independent organizations.

Our Partner

www.windtechnic.com

(871) 7 30 58 75 y 7 30 69 60

(871) 7 30 58 75 y 7 30 69 60